Before joining Fairfield Mfg., now part of Dana Corp., I had never designed anything or worked with off-angle gearing. I was a young engineer, curious, and ready to learn. And it didn’t take long before I successfully designed my first complete gearbox.

My ‘first’ was creating a new gearbox for Jacobs Wind Electric Co. in Minneapolis, Minnesota for one of its upcoming machines. Dating back to 1922, Jacobs was one of the earliest manufacturers of wind turbines.

Mentoring me through it all was my first boss and the one that I’d work for the next 29 years ― Jim Dammon, the longtime manager, and then vice-president of Fairfield’s custom gear and gearbox design engineering group.

Prior to my work at Fairfield, I was chief engineer at Schafer Gear Works, now Shafer Industries in South Bend, Indiana. There, I learned gear manufacturing: mostly parallel axis gearing, as Schafer did not make right angle gearing other than face gears and some fine pitch bevel gears.

The Jacobs design presented a few challenges. It was to have a shaft angle that was nine degrees off vertical, offset horizontally and was a speed increasing drive, rather than the much more common and more easily designed speed reducing drive. So, under Jim’s mentoring, I quickly learned all I could about Hypoid gearing, speed increasing gears, off-angle gearing, and shaft, bearing, seal and housing design.

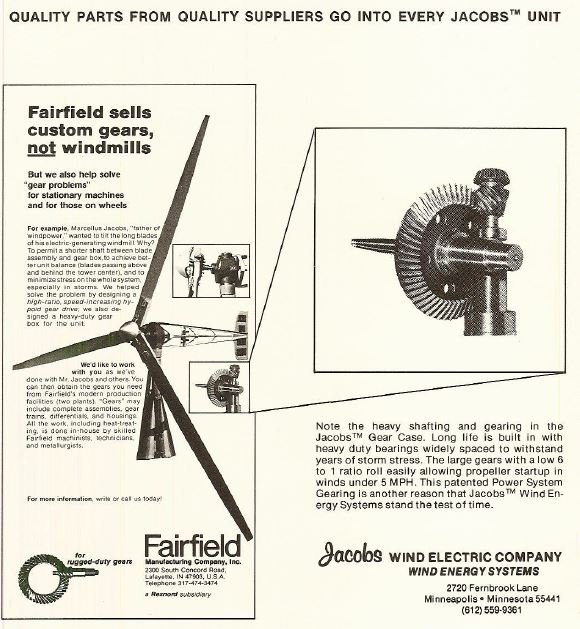

Rick Miller’s custom-designed gearbox featured in a 1980’s print ad by Fairfield MFG & Jacobs Wind Electric Co.

The result is pictured here. Some of these gearboxes are still in use today. Both Fairfield and Jacobs ended up displaying this gearbox in several of their print advertisements. Since then, Fairfield has used several more gearboxes of my design in their print advertisements.

When I first designed the Jacobs gearbox, I worked with M.L. Jacobs, the co-founder of the company and a legend and pioneer in the wind power industry. M.L. died a few years after I completed this project. Recently, I caught up with the co-founder’s son Paul, now president of the company his late dad co-founded. We reminisced about those days and how the wind energy business and Jacobs has changed over the years.

From those early days and since, the lessons I’ve learned are that you must start somewhere. Everyone does. It helps immensely to have a great mentor like I did in Jim Dammon. Working for a great company like Fairfield was beneficial as well. I appreciate the many opportunities I was provided there as a design engineer to grow and be creative.

Even though it was only a small machine; 10 KW and then 17 KW, I eventually designed gearboxes for wind turbines up to 300 KW.

My advice to my younger self: Don’t be overwhelmed when a task seems very difficult. Persevere and you can be successful, and it will be very satisfying. Believe in yourself and know that you can usually do more than you think you can.

That Jacobs gearbox was the start of what eventually became over 300 complete gearbox designs I created over a period of 36 years. Every project, including my three patented inventions, was interesting and rewarding. But I am proud of and will always remember my first.